|

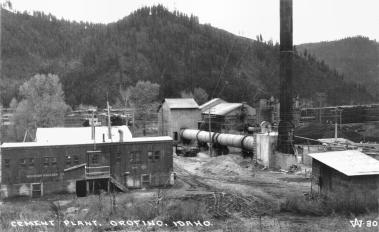

Don Gardner is the Winner!! The cement plant owned by Washington Idaho Lime Products which was located behind where Orofino Elementary School now stands is the answer to the 18th week of Orofino History Trivia Albert Wolverton worked at the plant for a number of years as did his father and brother. He helped provided most of the information for this week's history. The cement plant opened in 1936 and closed in 1948 due to complaints from neighbors about the dust and a law suit that was filed. The plant area covered most of the area where the Orofino Elementary School playground is now.  Making cement requires limestone and clay which were originally taken from the hill behind the plant. The limestone soon ran out and was then taken from the Jordan quarry located on Lower Fords Creek Rd. about three miles upriver from the Orofino Bridge. It was on Nez Perce Tribal ground and the lease required that some Native Americans be employed at the plant. Clay was also hauled from a pit on Gilbert hill. The limestone was run through a hammer mill which reduced it to fine powder. Then it and the clay in proper proportions was mixed with water and run through the raw mills. These were round metal cylinders filed about 1/2 full with one inch steel balls. These balls inside the rotating cylinders ground the mixture to a very fine mud called slurry. The slurry was pumped into one of the five tanks at the plant which were about 14 feet in diameter and 35 feet high. Slurry was kept stirred by motor driven paddles so that the solids did not settle to the bottom. These tanks had a large tunnel under them containing the piping and the pumping equipment. The slurry was then pumped to the kiln to be burned into clinkers. The kiln was a metal tube about 100 feet or a little more long and about 10 feet in diameter lined with fine brick. The kiln rotated and was heated by a coal fired burner to about 1800 degrees. This burned the slurry into clinkers or a volcanic-like rock. The kiln was on an angle so as it turned, the clinkers tumbled to the low end and where emptied onto a conveyor and moved to a stock pile. From there they went by conveyor to the ball mill and were ground to about the consistency of coarse sand. This went to the finish mill where it was ground to the final cement stage. The finished cement went by bucket elevator and conveyor to the pack house storage bins. Then it went to the sacking machine or to the conveyor to be loaded bulk into railroad box cars. The plant was capable of making 675 barrels of cement per day. (A barrel is 400 pounds.) During four years, it averaged 500 barrels per day. The plant made both Portland Cement which is commonly seen and high early cement which is a faster setting, much harder cement which was made primarily for construction at Hanford. Due to its importance to the war effort during World War II, it was priority for coal, though part of the time they used lower grade coal from Canada. A few years ago, the tunnel to the tanks was uncovered for a brief time on the playground behind OES. It brought the existence and history of the plant back to light and Wolverton spoke to the Clearwater Historical Society about the work done there. (Photo courtesy Clearwater Historical Museum) Monday: It is buried now. Tuesday: Like a rock. Wednesday: There was a railroad track to it. |

|||

| Window on the Clearwater P.O. Box 2444 Orofino, ID 83544 208-476-0733 Fax: 208-476-3407 |